hyperMILL automation

hyperMILL offers comprehensive options for optimizing and standardizing your NC programming.

By using the latest technologies, you can speed up your company’s production processes, make repetitive parts and workflows more efficient and thus compensate for the shortage of skilled workers.

- Shorter programming times

- Stored production knowledge

- Simple programming

- Fast and reliable detection of processing features

hyperMILL automation modules

hyperMILL automation comprises several key technologies that can be used individually or in combination, some of which are already included free of charge in the basic version of hyperMILL:

Identification and processing of recurring geometric features such as holes, pockets, threads, contours, etc..

Automated feature recognition enables fast and reliable programming

Saving machining strategies in macros for reuse in order to then apply them to recognized features / geometries

Adaptation of processing steps to specific materials and tools.

Management and virtualization of tools including technological data.

Automatic selection of the optimum tool and adaptation of the machining strategy.

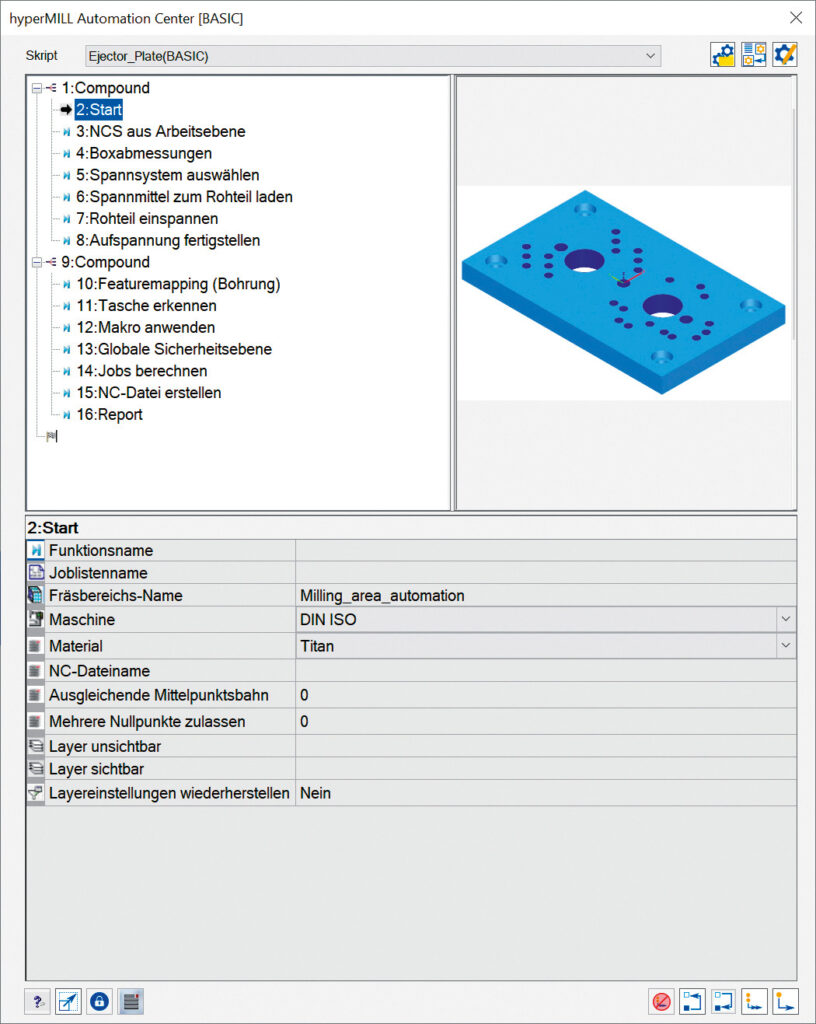

hyperMILL AUTOMATION Center

(Basic and Advanced versions)

Tool for defining and controlling automation processes.

Define and standardize complex manufacturing processes with the help of a “modular system”

- Ideal for automating simple processes.

- Including functions for job list creation, clamping device positioning and use of macros.

- No special programming knowledge required.

- Suitable for the automation of complex production processes.

- Full use of all hyperMILL CAM and CAD functions.

- Definition and standardization of all steps from data preparation to NC program creation.

Automation with hyperMILLoffers numerous advantages

Recurring geometries are automatically recognized and processed, which significantly reduces the manual programming effort.

Once “best practices” have been defined, they can be applied throughout production, resulting in uniform quality and efficiency.

Valuable know-how is stored and backed up in the macro database and is therefore available at all times.

Automation minimizes human error, which increases process reliability.

Even less experienced employees can achieve optimal results thanks to standardized processes.

Frequently asked questions (FAQs)

How can hyperMILL automation improve my production processes?

hyperMILL automation standardizes and accelerates recurring processing steps, shortening programming times and minimizing errors.

What advantages does the hyperMILL AUTOMATION Center Advanced offer?

The Advanced Center enables the automation of complex processes and offers comprehensive functions for defining and standardizing all production steps.

Mechatronics & Robotics

Mechatronics & Robotics