Voxeljet VX200 HSS

The ultimate R&D platform for polymer 3D printing

The VX200 HSS is one of the world’s most flexible 3D printers for polymers. An open system with full access to process data, freely configurable print parameters and an integrated data analysis tool, it is ideal for research and development of new materials for polymer 3D printing in addition to the production of series parts and prototypes.

- Variety of materials

- Smart operation

- Cost-efficient

- Precise in detail

- Compact

Variety of materials

The open source software enables full access to all printing process parameters as well as individual adjustment of the temperature sources for individual adaptation to your material.

Smart operation

The VX200 HSS can do a lot – but operation remains very simple thanks to a well thought-out ergonomic concept.

Cost-efficient

Small series components can be produced just as quickly and precisely with the VX200 HSS as initial prototypes and design iterations.

Precise in detail

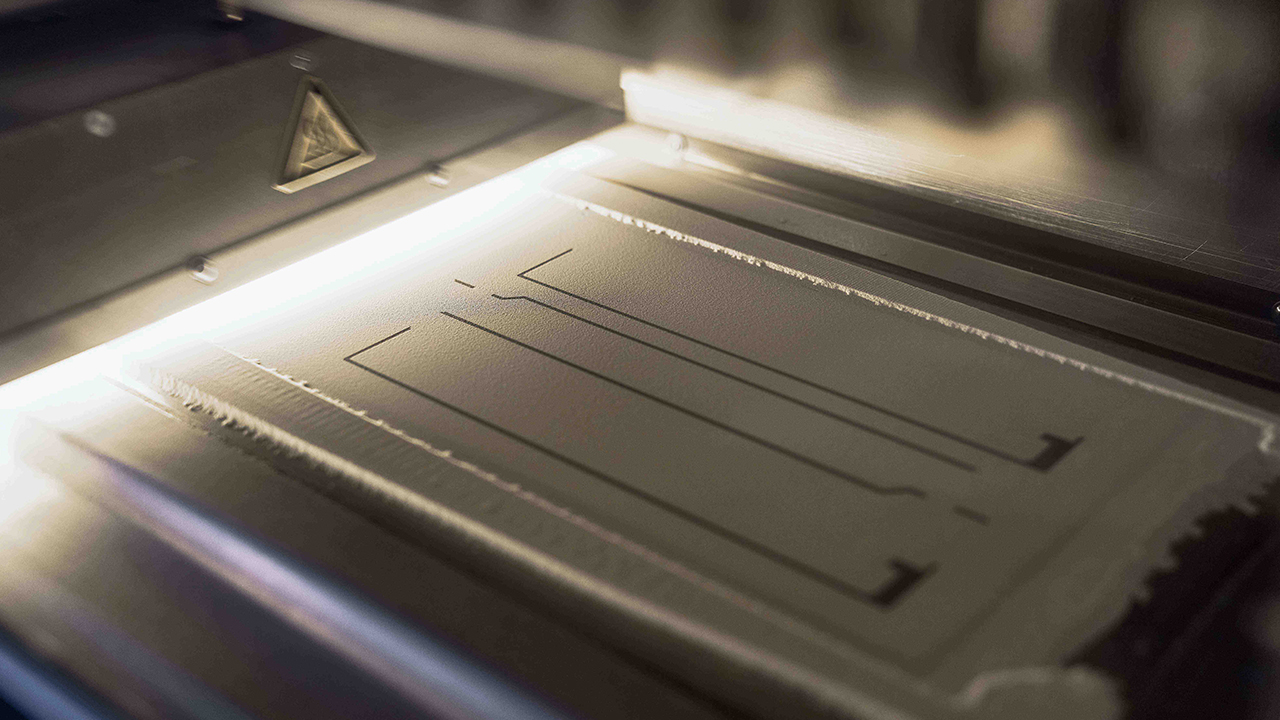

With a resolution of up to 360 dpi, depending on the material configuration, the VX200 HSS prints even the finest details with impressive precision.

Compact

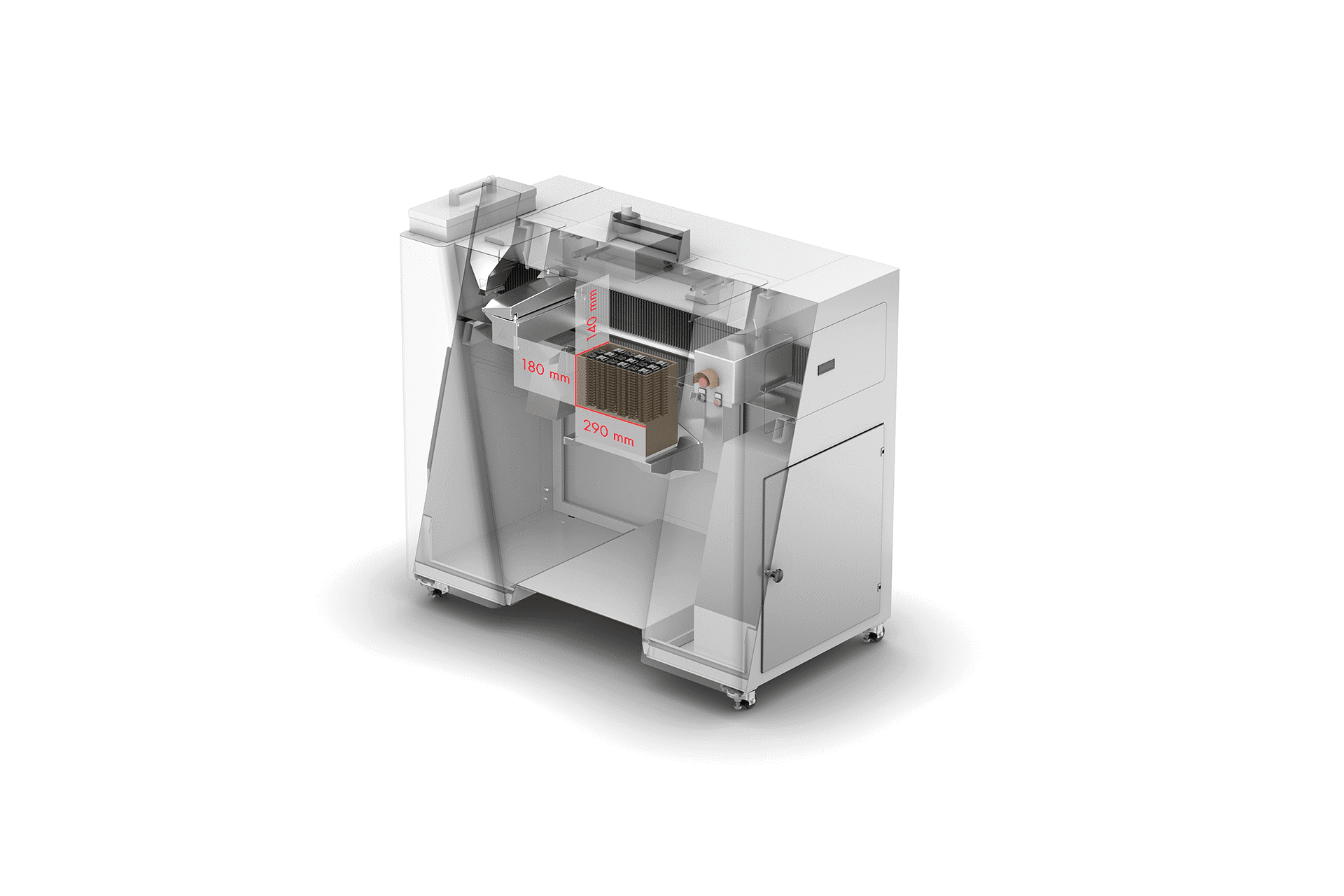

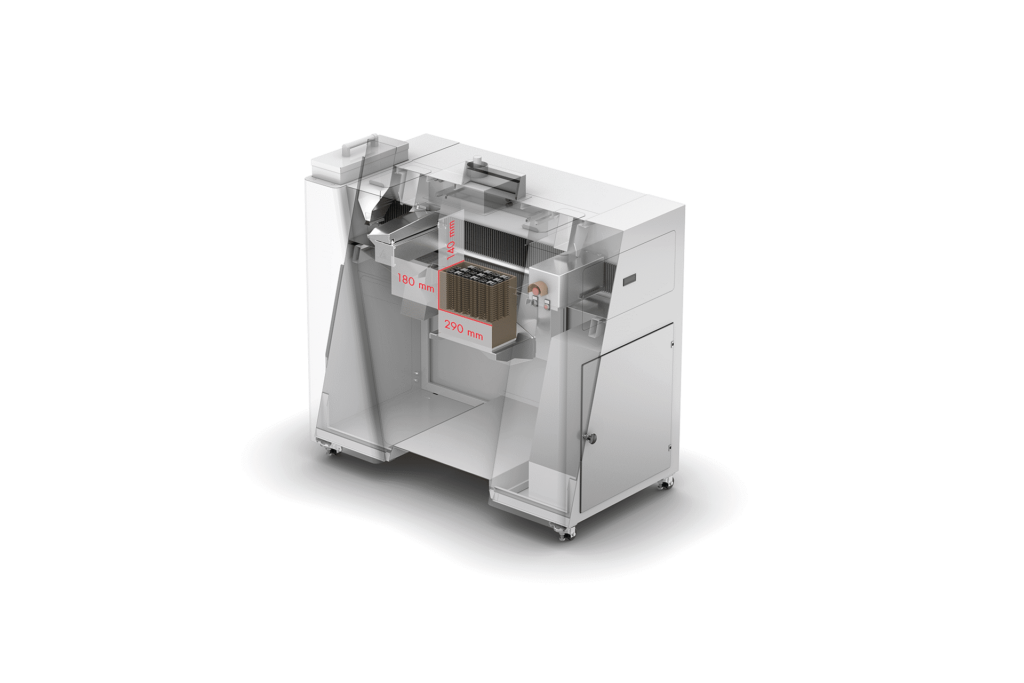

The VX200 HSS can also be used in smaller production areas or research laboratories without the need for peripheral devices.

“We want to process different materials with our VX200: from PA 12 and PA 613 to PEBA. However, we are not limited in our material portfolio. The HSS technology from voxeljet makes it possible to optimize the interaction between material and machine and thus offer the best possible material.”

Frequently asked questions (FAQs)

Welche Vorteile bietet die Open-Source-Software des Voxeljet VX200 HSS für die Anpassung der Druckparameter?

The open source software of the VX200 HSS gives you full access to all printing process parameters, allowing precise customization to your material and requirements. This optimizes print quality and speed and enables the processing of many different materials.

Wie beeinflusst der Bauraum von 300 x 200 x 150 mm die Flexibilität des Voxeljet VX200 HSS bei der Produktion?

The installation space of 300 x 200 x 150 mm offers you the flexibility to print both small and medium-sized components efficiently. This allows you to process various projects and prototypes with different requirements in a single printing process.

If larger components or higher quantities are required, you can easily transfer production within the voxeljet VX series to other, larger systems of the same series. LINK VX1000HSS

Wobei kann mich die HSS Technologie unterstützen?

Time to market – Shortened development and production times in design and function allow you to bring your products to market much faster.

Geometric freedom –Additive production removes the manufacturing limitations of conventional processes. Anything that is conceivable in terms of design can be printed. For products that are lighter and more efficient or simply push the boundaries of what was previously possible.