- Tailor-made system selection for you!

- Accuracies up to 0.001mm

- Maximum resolution

- Advice and support from specialists before and after surveying

- Enthusiastic, motivated team of experts

- Shortest throughput times due to available capacities

- Pick-up and delivery service

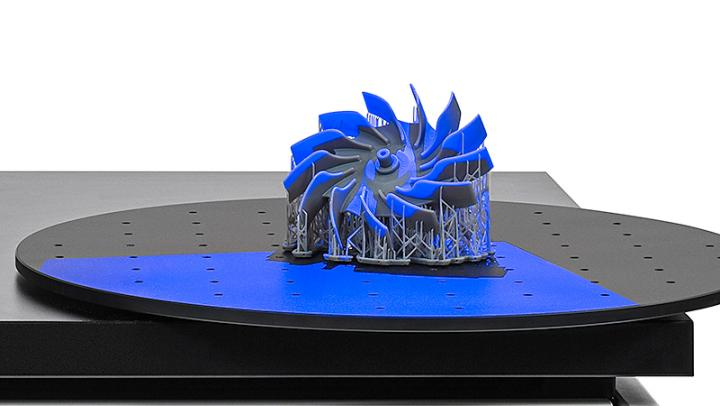

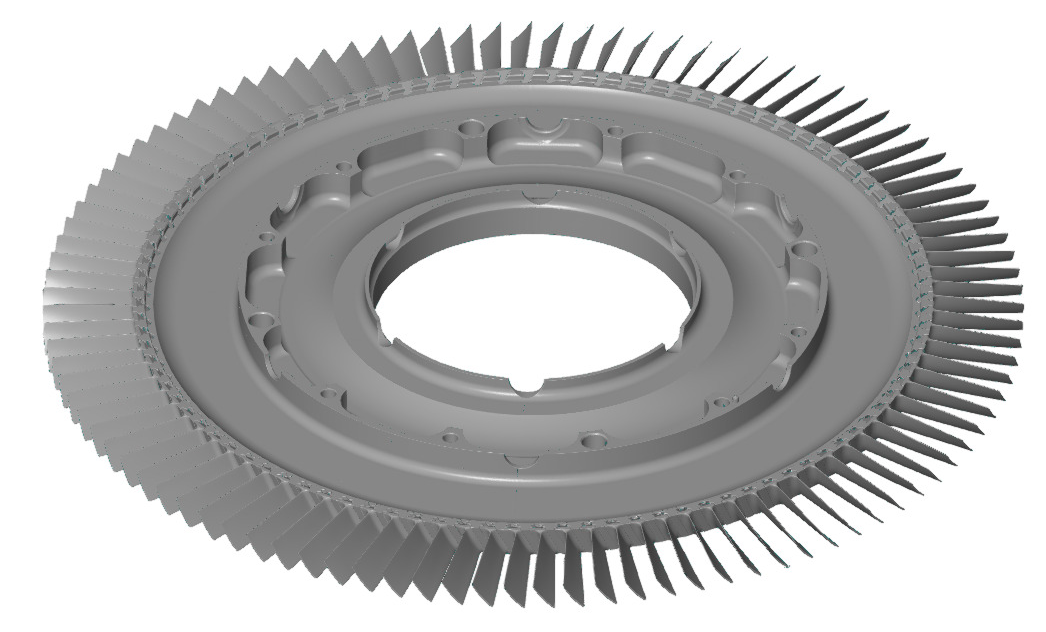

Industrial 3D scan

With the metrology solutions from ZEISS, we set the standard on the market for

high-quality 3D scans in Austria, Liechtenstein and Switzerland.

As a certified ZEISS Metrology partner, we always have access to the latest

measuring systems and can therefore guarantee the best equipment for the respective application.

measurement project.

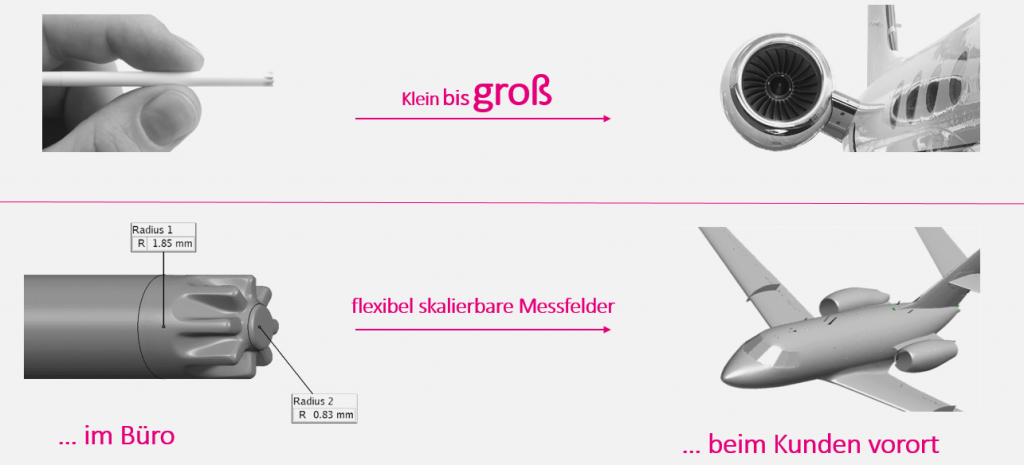

When it comes to 3D scanning, we are virtually size-independent – from the pinhead to the

aircraft, we have already demonstrated our capabilities.

The cost of an industrial 3D scan of a simple component usually starts at around €/CHF 120.

ZEISS measuring systems

Our 3D measuring systems can be operated both manually and automatically. Automation is ideal for measuring larger component packages or for tests during series production.

Thanks to the mobility of our hand-held 3D scanners, measurements can also be taken at our customers’ premises without any problems. Alternatively, we look forward to your visit to one of our 4 measuring rooms in Austria and Switzerland!

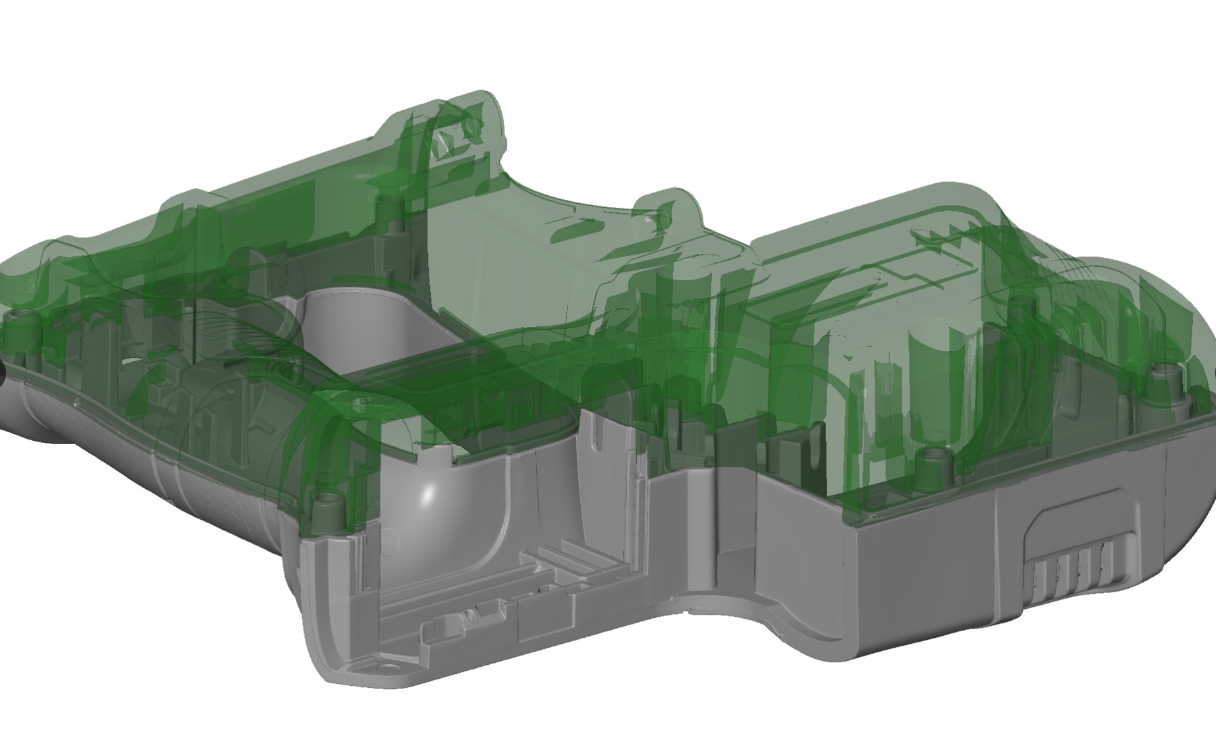

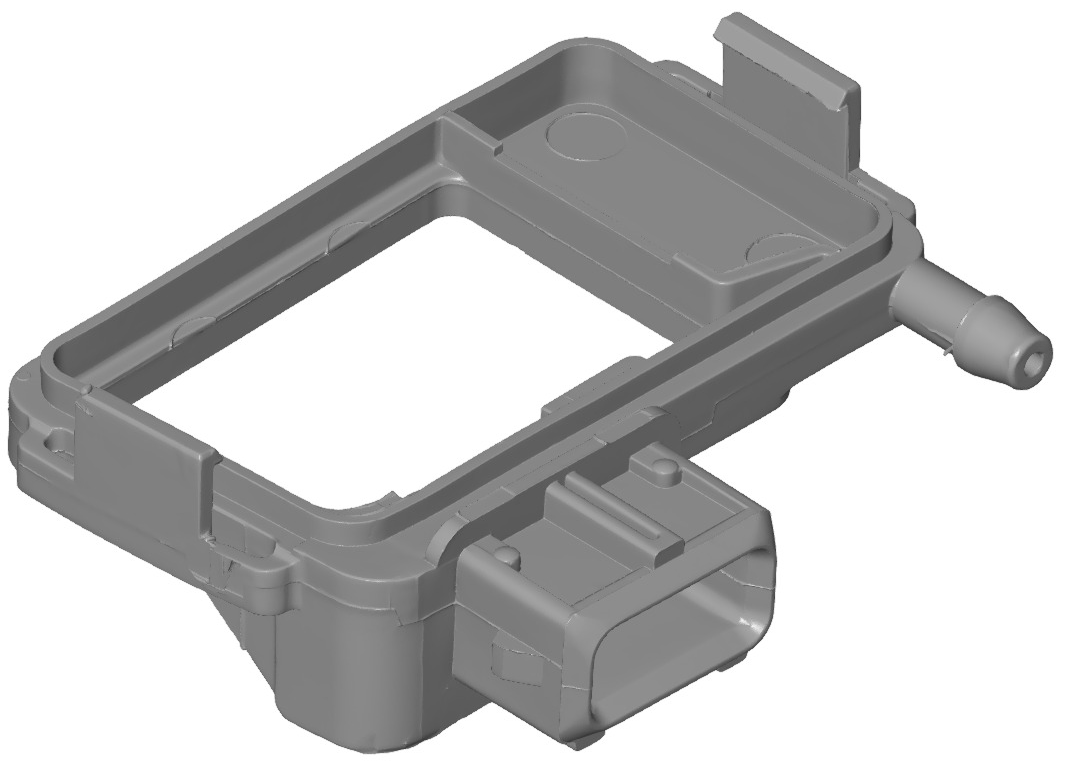

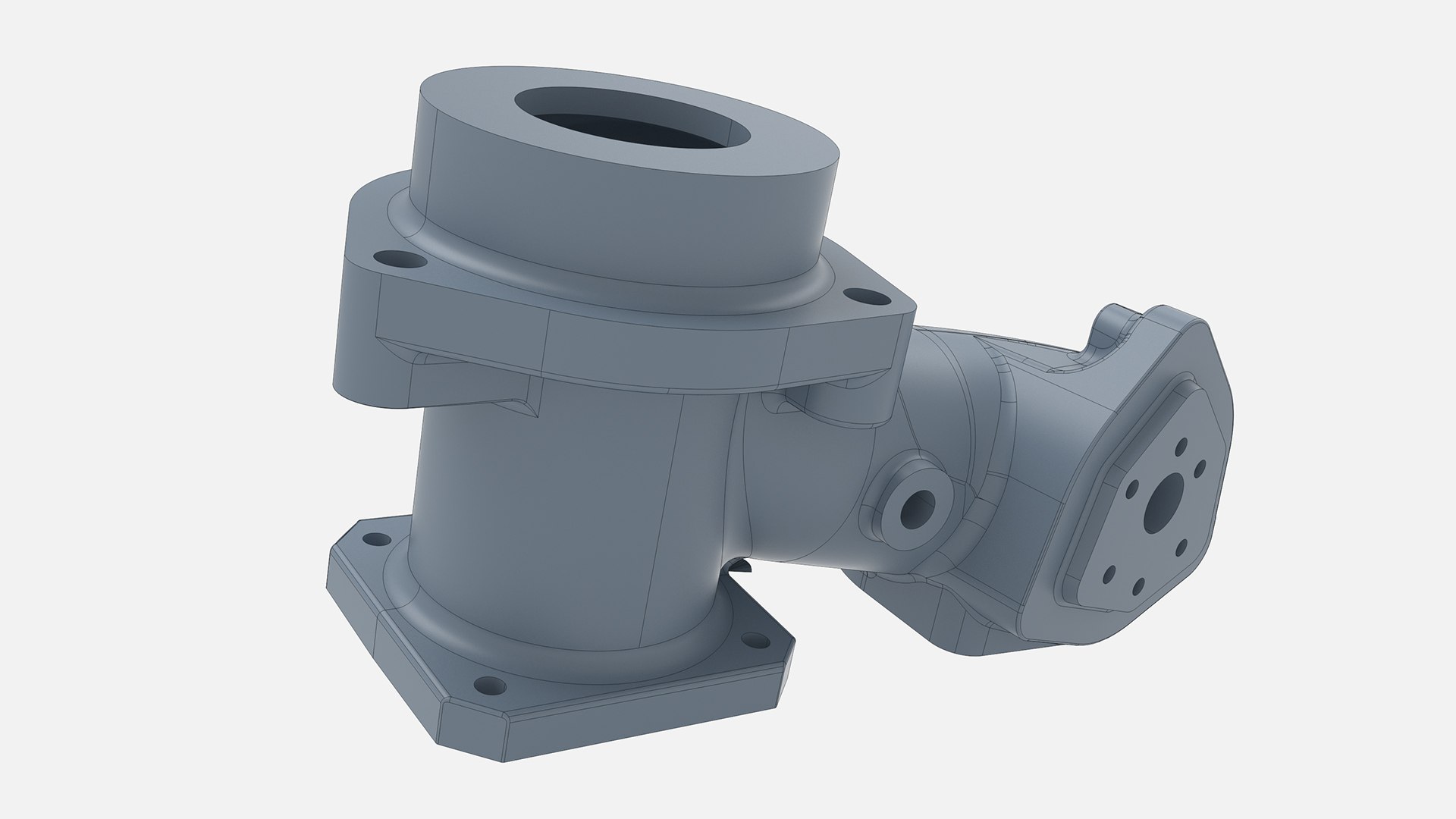

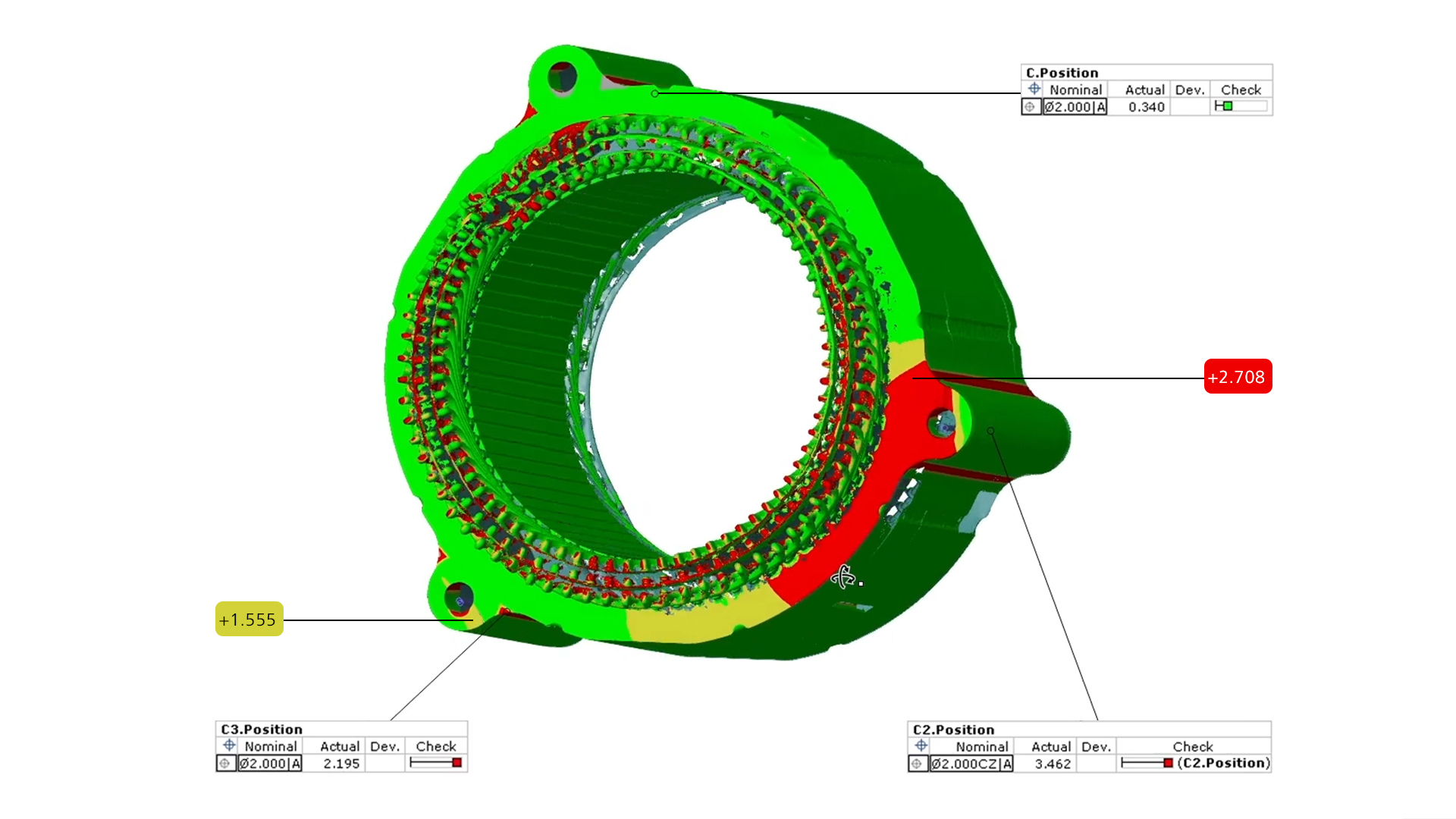

The range of applications for optical 3D Metrology is very broad. In industrial applications, for example, the focus is usually on maximum precision and process reliability for quality assurance or reverse engineering.

In contrast, the design and art industry often requires the digitization of real or haptic components. Once these models are digitally available, all further steps in the engineering and production process chain can be run through.

Frequently asked questions (FAQs)

How much does a 3D scan cost?

The cost of an industrial 3D scan of a simple component usually starts at around €/CHF 120. However, it is very difficult to make a general statement about the actual cost, as this depends on several factors. These include, for example, the complexity and size of the component as well as the application and the necessary post-processing. Such post-processing could be, for example, quality assurance, i.e. checking the dimensional accuracy in comparison to a target model, or reverse engineering, where a CAD model is created from the 3D scan data for further processing.

The best thing to do is to simply contact us for clarification and, after expert advice by e-mail(metrology@westcam-group.com) or by telephone, we will be happy to provide you with a non-binding quote.

What information does WESTCAM need to submit an offer?

In order to be able to provide you with a meaningful and, above all, interesting offer, we naturally need some specific information from you. On the one hand, information about the component or components themselves (size, weight, material and number of components to be measured) and, on the other hand, which application is involved and what expectations you have of our service. The best way to send us this information is by e-mail to metrology@westcam-group.com: CAD models, drawings, photos. The better we can get an idea of your task, the more tailored our offer can be.

How long does a 3D scan service at WESTCAM take?

With normal workloads, 3D scans can be completed within a few days. If you have a time-critical project, please contact us explicitly. The time required for the actual 3D scan depends on several factors, such as component size and complexity as well as surface quality, and can vary greatly depending on the application. We will of course be happy to advise you on this, try to meet your desired deadlines and achieve the shortest possible turnaround time. Just send an e-mail to metrology@westcam-group.com and we will get back to you as soon as possible!