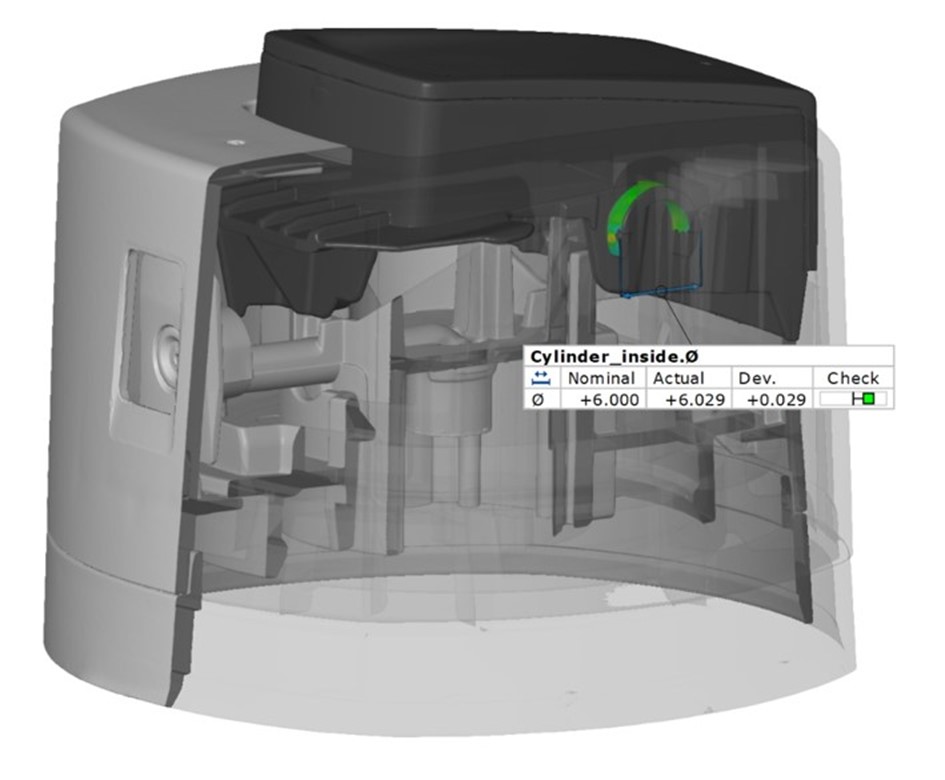

- Evaluation of internal structures

- Blowhole analysis

- Assembly analysis

- Internal geometry control

- Digital twin

- Wall thickness analysis

Industrial computed tomography for component inspection

Computed tomography is well established in medicine and has become indispensable. Gradually, this technology – modified accordingly – is also finding its way into the industrial environment: With the help of industrial computed tomography, it is possible to digitize components including internal structures in a non-destructive manner.

There are a wide range of applications that make analysis and inspection tasks in different industries much easier

Geometric inspection of internal component areas

There are major advantages in the dimensional evaluation of internal structures of plastic or cast components, for example, which no longer need to be destroyed in order to be measured. The technical CT measurement therefore supports initial sampling, tool correction, but also inspection during series production.

Blowhole analysis and structural errors

The detection and evaluation of air or gas inclusions, which can have an impact on component function, is another major field of application for CT digitization. The size of the inclusion, the volume and the distance to the outer contour of the component are typically evaluated here.

Analysis of assembly situations

In the case of assemblies made up of different components, the interaction of the individual parts inside is often of interest. Here too, industrial computer tomography provides support. The evaluation of the current assembly situation is the proverbial “look inside”.