Q10plus

Maximize your production with high-precision electron beam technology.

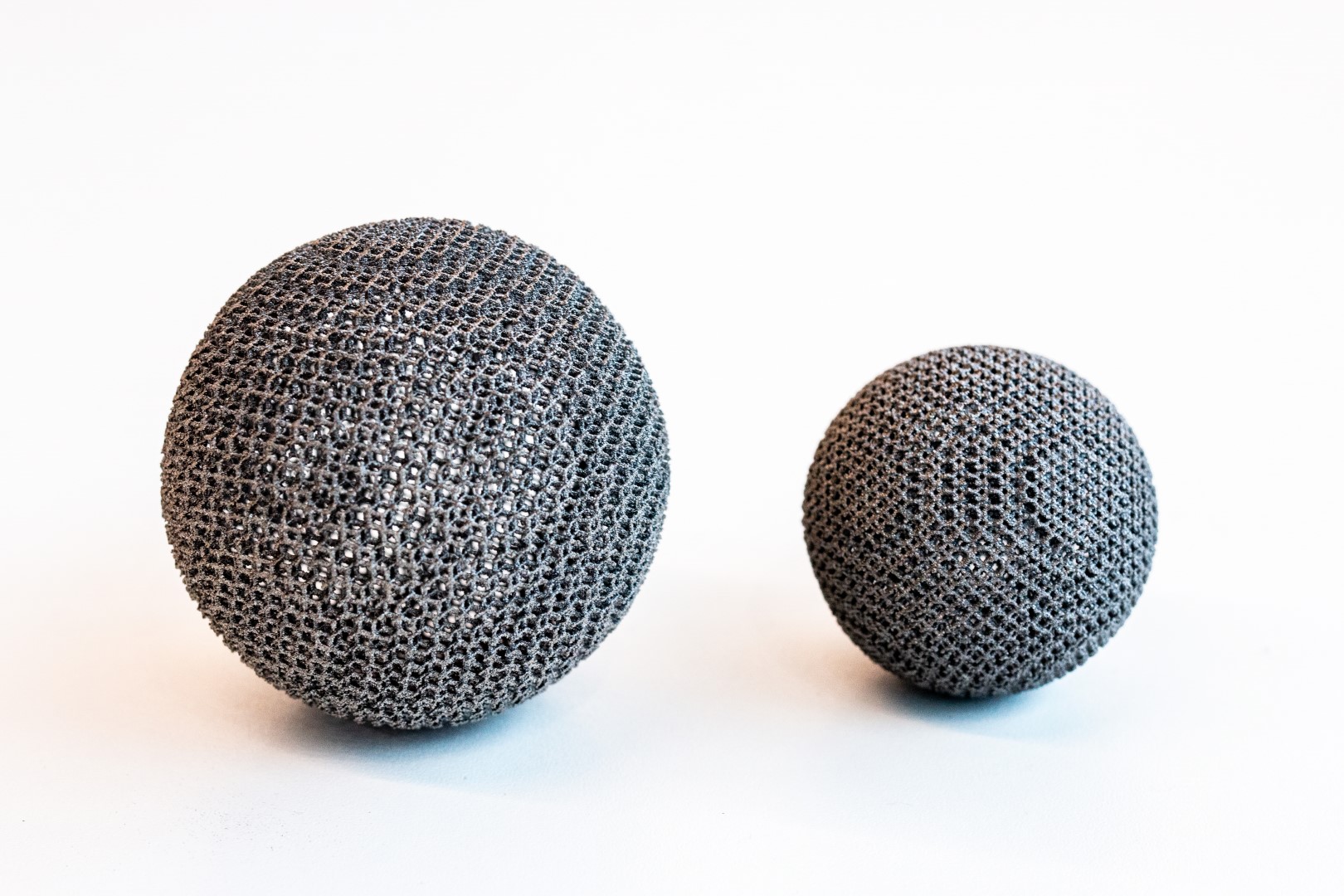

Electronic Beam 3D printing for the manufacture of individual products such as orthopaedic implants and series production of industrial components.

Thanks to a technological breakthrough in electron beam melting, components can now be manufactured in metal “without support” and without connection to a building panel.

Thanks to the supportless design, the installation space can be utilized to its full height by stacking, which further increases the productivity of the machine.

- Auto-calibration and inline quality check

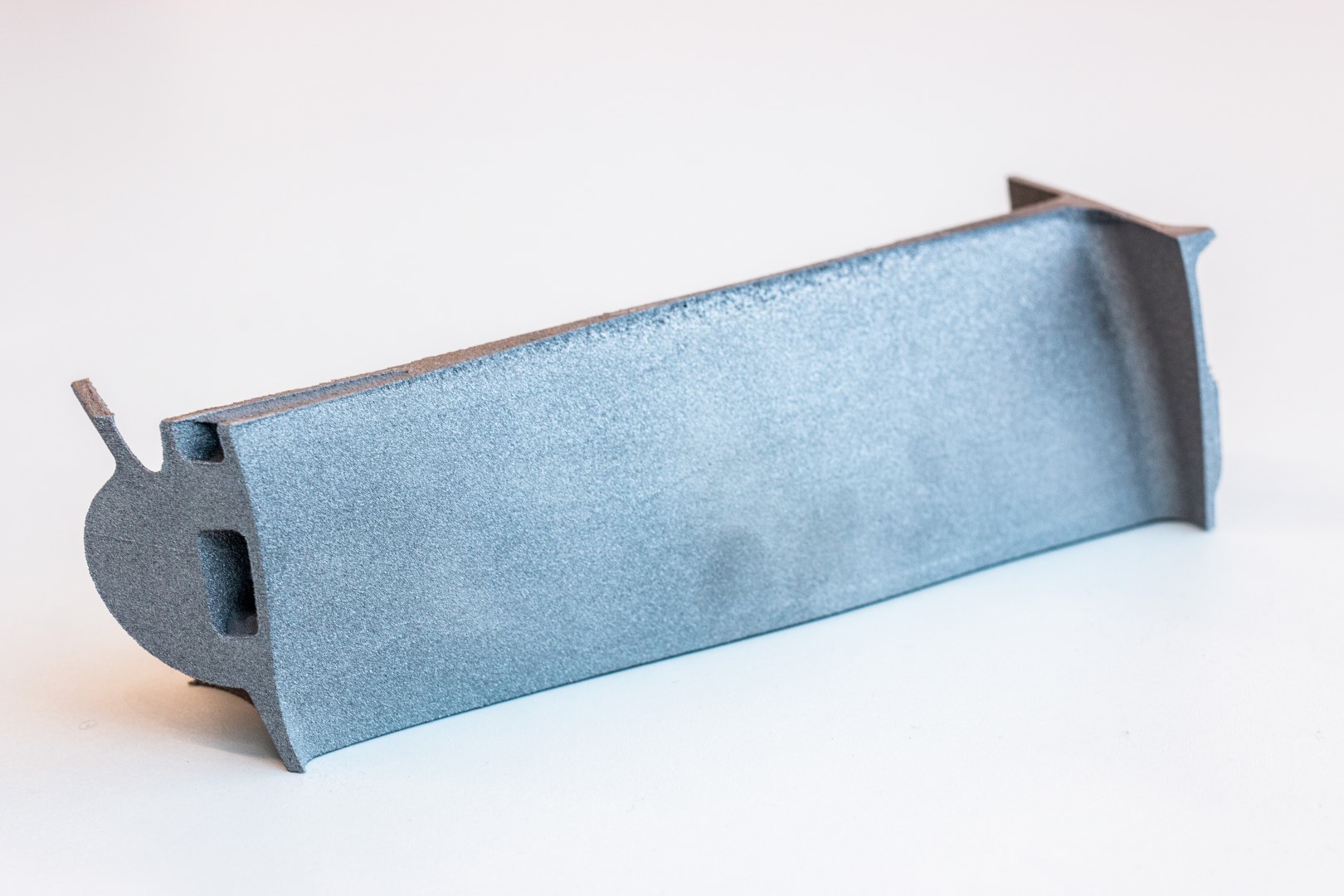

- Optimized surface quality

- Building without support

- Stacking of components

Autocalibration & inline quality check

The manufacturing accuracy of the Q10plus has been redefined by the integration of xQamTM technology, which enables extremely precise auto-calibration.

At its heart is the LayerQamTM system, a camera-based monitoring tool that ensures the quality of every manufactured part in real time.

Optimized surface quality

The high-temperature vacuum atmosphere of the Q10plus enables you to process reactive materials efficiently.

This reduces residual stresses and porosity in the components, resulting in a higher surface quality and structural integrity.

The new point melt process enables surface qualities to be achieved that are familiar from laser systems.

Frequently asked questions (FAQs)

How does the Q10plus improve production accuracy?

The new point melt process enables surface qualities to be achieved that are familiar from laser systems.

What advantages does the high-temperature vacuum environment of the Q10plus offer?

The high-temperature vacuum environment reduces residual stresses and porosity in the components, resulting in improved structural integrity and increased surface quality. This enables efficient processing of reactive materials and improves production accuracy.

Stress-free annealing of the components, as is usual with laser systems, is not necessary and therefore saves a lot of time.

Which operating system does the Q10plus use?

The Q10plus runs on a specially adapted operating system that is optimized for the requirements of electron beam powder bed fusion (EB-PBF). This system ensures stable and reliable operation, which is essential for precise and efficient production.

Mechatronics & Robotics

Mechatronics & Robotics