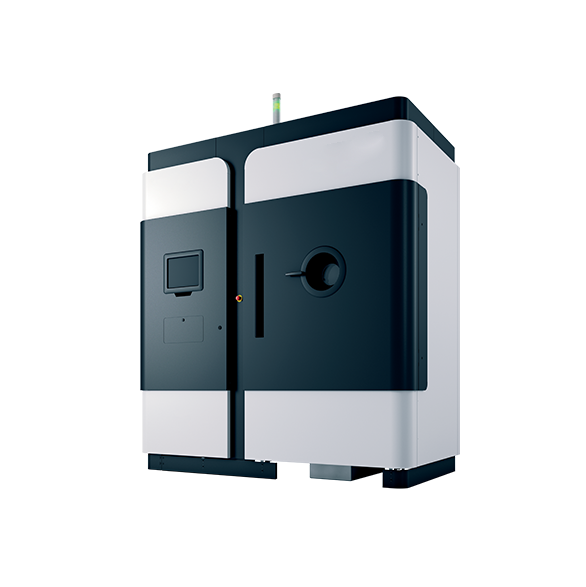

Spectra H & L & M

Precision meets performance – from outstanding melting performance to mass production on a large scale

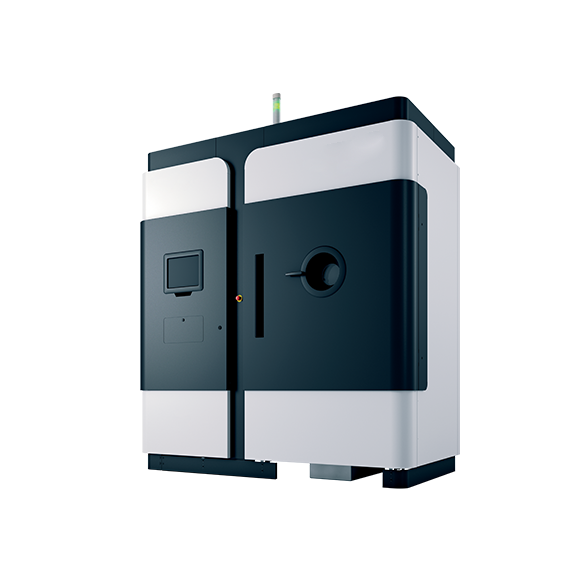

Colibrium Additive Spectra H, Spectra L and Spectra M are state-of-the-art EB-LPB printers that ensure fast and efficient production of high-quality metal parts .

The Spectra H is the workhorse of the Spectra family. With its 6kW electron beam, it achieves the highest build quality with incomparable component quality. The high energy density means that even high-alloy tool steels can be processed.

Spectra L & M are primarily designed for the production of titanium and titanium alloys.

- Production of refractory materials

- Space heating up to 1000C°

- Highest installation rates

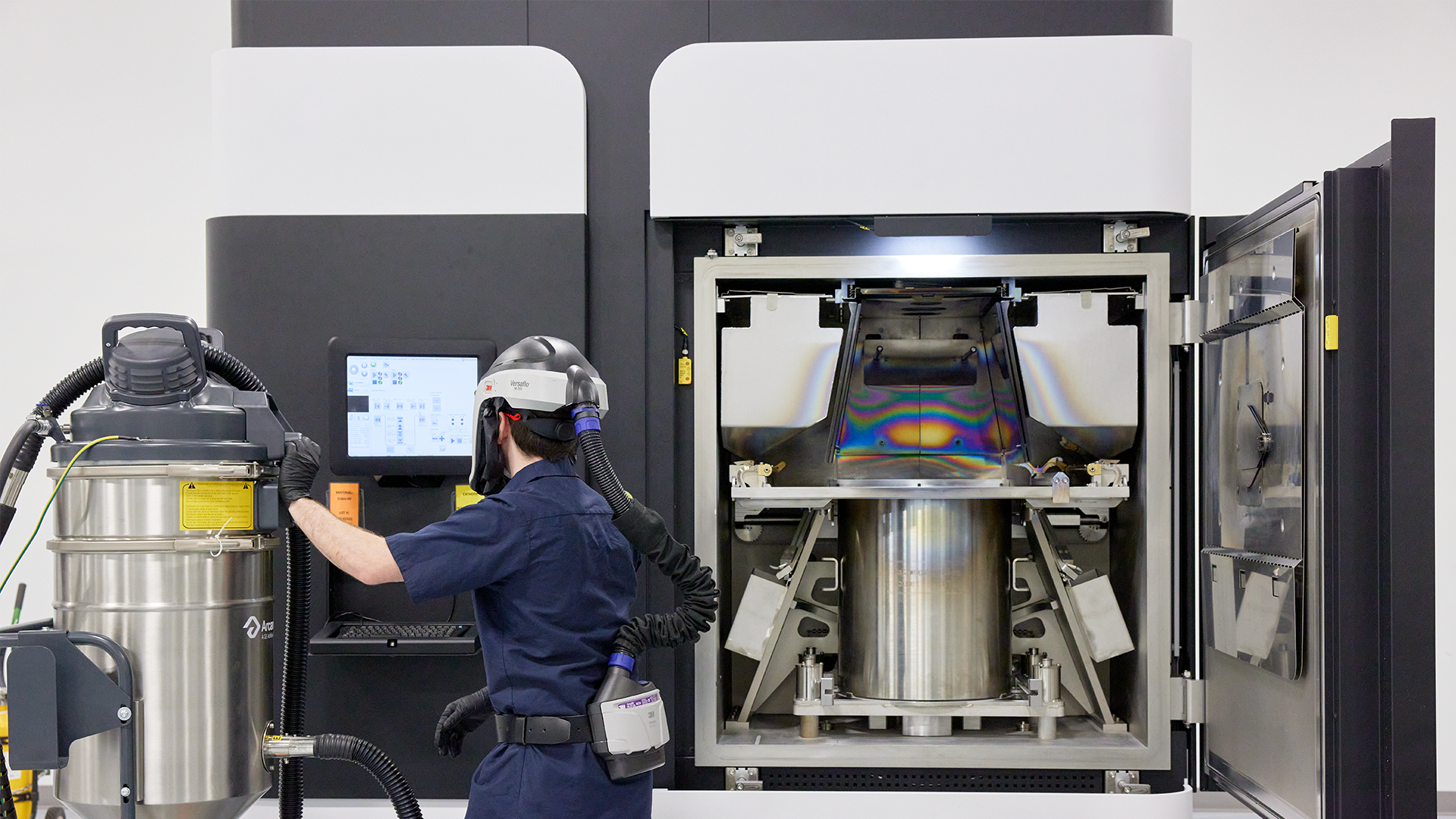

Electron Beam – Layer Powder Bed

EB-LPB technology uses an electron beam for the additive processing of metal powder.

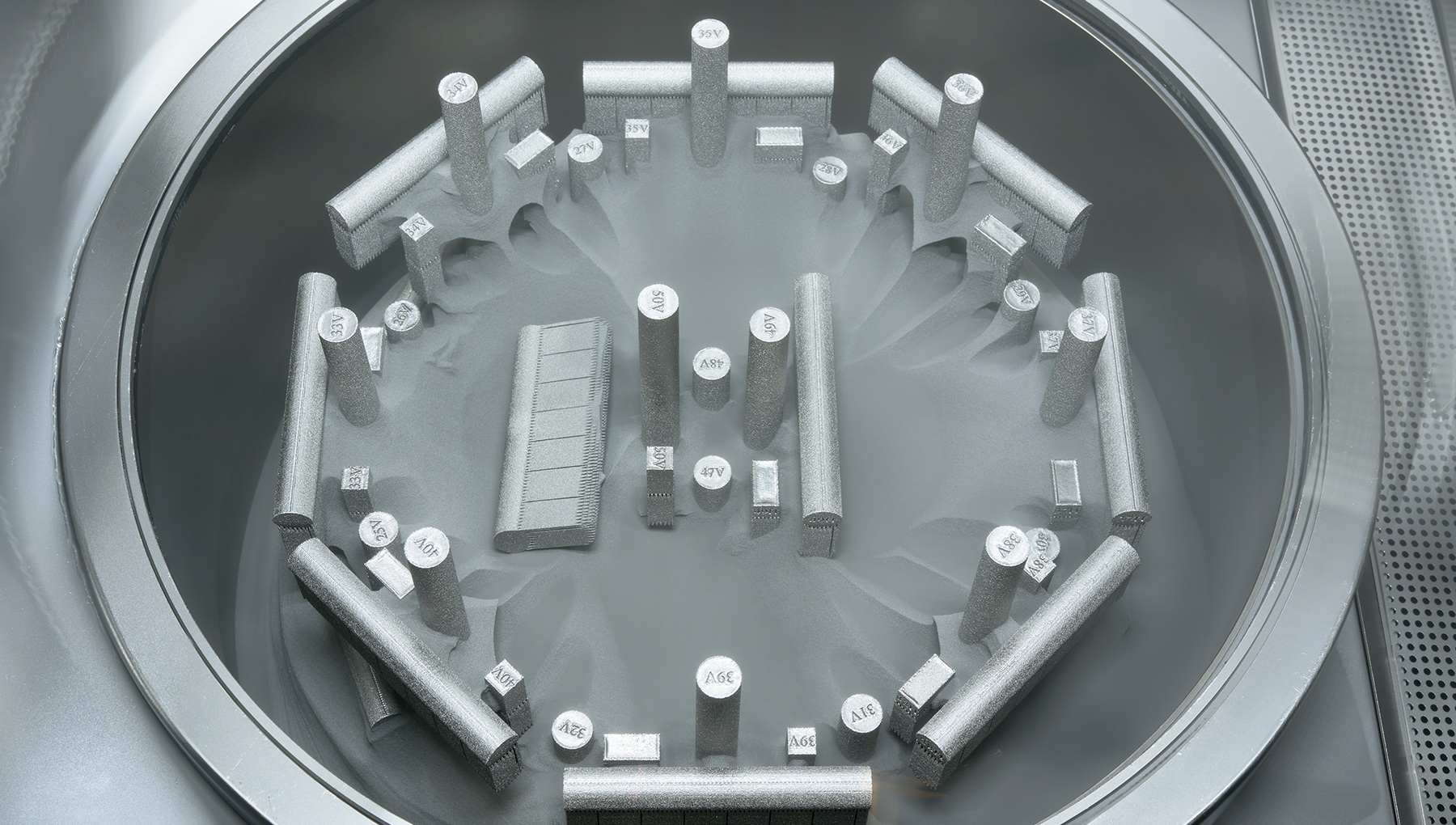

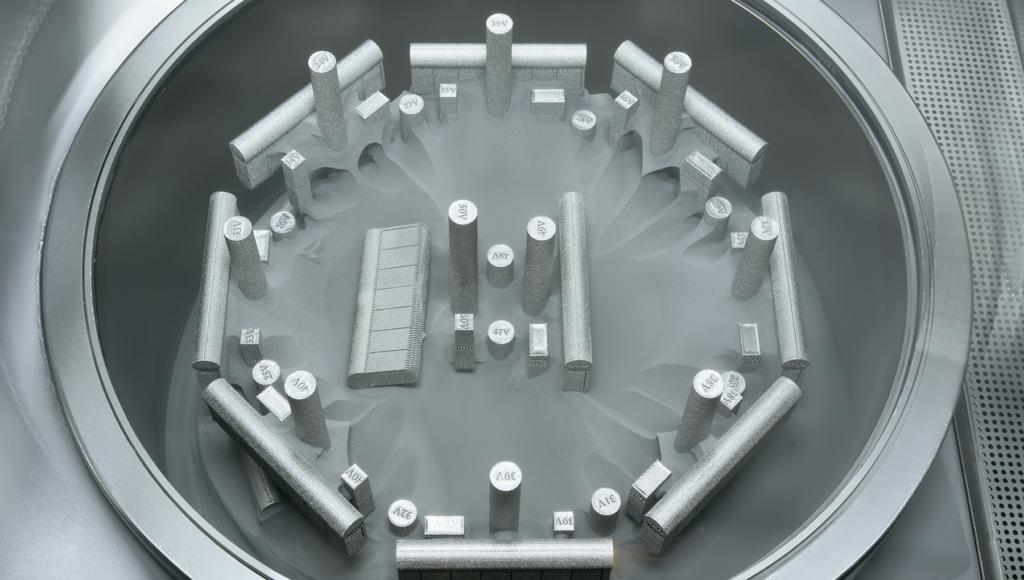

EB-LPB technology is characterized by its ability to stack parts tightly and on top of each other.

This maximizes production efficiency while ensuring high quality and density of the components produced.

Spectra H

The Spectra H’s exceptional melting performance and precise temperature control ensure uniform material properties and excellent surface quality. This modern EB-PBF machine is ideal for the production of complex and high-precision metal parts.

Spectra L & M

The large construction volume allows the mass production of high-quality parts.

The special EB-PBF technology makes it possible to stack parts tightly without any loss of quality, which leads to a significant increase in production capacity.

Frequently asked questions (FAQs)

What is the difference between EB-PBF and SLM in additive manufacturing?

EB-PBF (Electron Beam Powder Bed Fusion) fuses metal powder using an electron beam, while SLM (Selective Laser Melting) uses a laser.

EB-PBF is characterized by a higher material density and lower stresses, while SLM is suitable for more complex geometries.

What are the main features of the Spectra H printer?

The Spectra H is characterized by exceptional melting performance and precise temperature control .

This advanced EB-PBF technology enables the production of high-precision and complex metal parts with uniform material properties and excellent surface quality.

Thanks to the high energy density of the 6 kW electron beam, even high-melting steels and alloys can be processed.

How does EB-PBF technology improve production efficiency?

EB-PBF technology enables the building bed to be preheated to 1000C° using the electron beam.

This minimizes internal stresses in the component and eliminates the need for subsequent stress-free annealing as with lasers. Due to the high energy density, significantly higher build rates can be achieved.

In the EBM process, a coarser, less expensive powder can be used, which significantly reduces the cost of the component.

Mechatronics & Robotics

Mechatronics & Robotics